Novosound

Novosound developed and patented a technique to mass-manufacture printable ultrasound sensors, for medical and industrial applications.

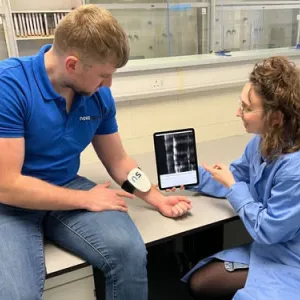

Novosound, headquartered in Glasgow, has revolutionised the manufacturing of ultrasound sensors with its patented thin-film technique, enabling mass production of low-cost, high-temperature sensors. These innovative sensors are used in both medical and industrial applications, including non-destructive testing (NDT) in the oil and gas industry, nuclear power stations, and petrochemical refineries. By simplifying complex inspections and enhancing condition monitoring, Novosound’s technology reduces operational downtime and costs across various sectors such as Power Generation, Aerospace, Renewables, and Healthcare. Their customisable and scalable solutions are designed to meet the needs of modern industries, making ultrasound integration more efficient and widespread.